VR Training System for Industrial Assembly

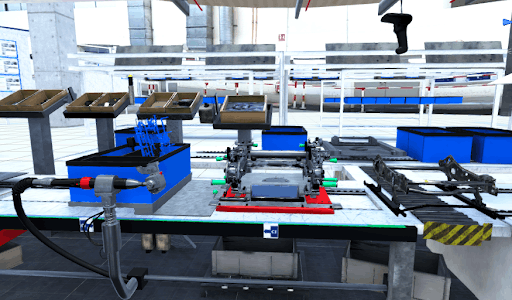

This project involved creating an immersive virtual reality training environment that simulates real-world industrial assembly processes. The system was designed to train operators in car seat assembly procedures, reducing training time and improving safety protocols. The VR environment provided realistic haptic feedback and detailed visual instructions, allowing trainees to practice complex assembly tasks without the risks and costs associated with stoppping production lines for training.

Duration

2 years

Team Size

1 developer + 1 designer

My Role

VR Developer

Technologies Used

UnityC#OptitrackVRMotion TrackingIndustrial Design

Key Challenges

- Implementing precise motion tracking for assembly tasks

- Creating realistic physics simulations for industrial components

- Optimizing performance for VR headsets

- Designing intuitive user interfaces for industrial workers

- Implementing inverse kinematics techniques for realistic hand movements like FABRIK

Key Outcomes

- Increase partner revenue by avoiding stopping production lines for training

- Reduced training time by 50%

- Enhanced safety protocols compliance

- Positive feedback from industrial partners